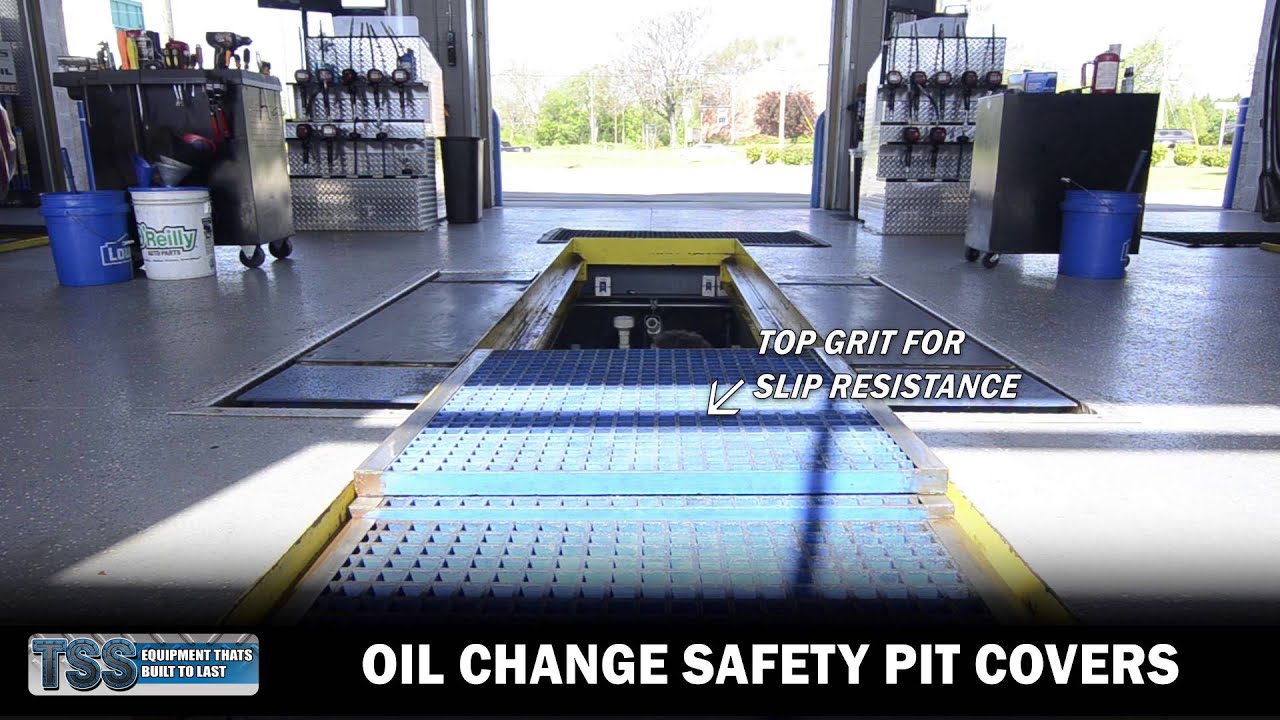

1-12 H - High strength molded fiberglass with top grit and St. Oil water and fluid spills are safely contained in the bottom of the Zip Pit for easy clean-up.

The design of the above-grade lube pit enables the technicians to work both top and bottom of the vehicle concurrently.

. As a result we have developed an unrivalled knowledge and understanding of the commercial vehicle. 42 - room for 2 people to pass within pit. Fiberglass cover with St.

I am a project manager for a real estate development firm. The Zip Pit is a pre-molded one piece unit designed for secondary containment with an above-grade lube pit enables the technicians to work both top and bottom of the vehicle concurrently. Never paint your pit covers again.

Plus our elevated solutions can be used for a variety of purposes from total vehicle wheel alignment to changing the oil in a customers truck. Our powerful waste oil pump can drain the waste oil tank in approximately 3 minutes. Oil Change and Service Bay Safety Nets OVERVIEW If your facility has service pits you must comply with OSHA regulations by regularly using a protective covering or guard to prevent dangerous falls into the pit.

All locations have a lube pit basement under the bays where oil changes are completed. Comes in multiples of 36inch and width varies see below Construction. OFFICE OF OIL AND GAS Design and Construction Standards for Centralized Pits The following design standards for centralized pits utilized by natural gas production operations to store wastewaters eg.

Other pit features such as lighting and accessories can also be installed prior to transportation to site. Comparing a Pit to the below surface work area of a drive-through oil change service station is the same as comparing a duck to an eagle. The most durable and best quality quick lube pit covers in the industry.

Zip Pit The Zip Pit is a pre-molded one piece unit designed for secondary containment. How does Express Oil Change Tire Engineers perform services so quickly. Hardware and HDPE durable side plastic glide strips Light weight cover that slides easily for stacking when car is being serviced PRICES BELOW ARE BASED ON MAXIMUM PIT OPENING.

Our custom built oil tank is conveniantly located within the pit itself and has many unique features. At ILS we specialize in facility planning EnviroLube installation equipping training and business analysis for automotive dealerships service facilities quick. Over the years Premier Pits have supplied a vast number of companies involved in the manufacture sale and operation of commercial vehicles.

It allows the full service oil change to be completed in the target time frame of 10 to. OIL CHANGE SAFETY PIT COVERS. It is also more ergonomically efficient.

Why do I hear a voice from underneath my car. The Zip Pit leak-proof design is environmentally friendly. Aluminum structure St.

Our exclusive design lets the technician work all day without dumping the tank. Above photo is at a Truck Oil Change Facility. Have lower PVC chase 2 maybe hooked to exhaust fan to remove heavy gases.

With a number of custom pit machines available our configurations are perfect for the shop with a dedicated alignment bay. Currently our architect and engineers are designing each of the facilities with ventilation systems in the lube bays. Track system to eliminate lateral movement and provide stability.

We answer some of your burning quest. The Auto Service Pit ASP System is housed within a concrete-lined sealed full-service automobile service pit which eliminates the need for costly and hazardous basements or high-maintenance risky high-lift systems. Oil drain tank and air pump to move waste oil to bulk tank.

The standard Zip Pit is a pre-molded one piece fiberglass unit designed for easy and efficient access to services performed below a vehicle and uses a patented technology. The significant advantage of a prefabricated drop-in pit is the construction time on site is greatly reduced. Integrated Lube Services is the exclusive distributor and installer of EnviroLube the environmentally friendly alternative to the standard concrete lube pit and lube basement.

The pit is recessed 4 feet below ground level and a technician in a patented seat on rail system is able to comfortably. Drilling or hydraulic fracturing fluids shall be accomplished in such a manner as to protect the health and safety of the. Our Waste Oil Pump System.

TSS Oil Change Equipment and Signs. Evolving Workshop Technologies can project manage the entire installation or can supply just the drop-in pit fitted with the EWP. Each pit is shipped with its own waste oil pump.

Custom fabricated to ensure durability and comfort. Have upper 8 or 10 PVC chase with cutouts every 5 feet - room for air electric lights. In most cases we will have a convenience store car wash school or other building that is close to your ideal design parameters.

Also save weeks waiting for engineers and architects to submit drawings for your consideration. Side channels for ease of gliding. One of our clients is an automotive repair facility that also performs oil changes.

Modular construction can be disassembled and moved a criteria for 7 year depreciation. These include local and national transport operators truck manufacturers and dealerships. Lots of easily accessible storage at pit level.

Oil Change Safety Pit Covers Oil Change Pit Change

Tss Oil Change Equipment Youtube

Pit Equipment Accessories Oil Changes Evolving Workshop Technologies

Pit Equipment Accessories Oil Changes Evolving Workshop Technologies

Tss Oil Change Equipment And Signs

0 comments

Post a Comment